All Products

-

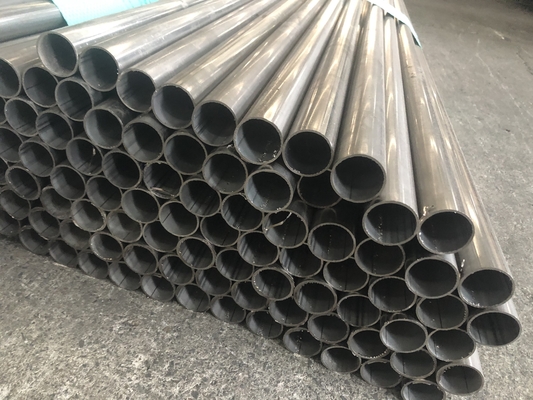

Diego NemerThe quality of the pipes is very good, very nice seamless pipes!

Diego NemerThe quality of the pipes is very good, very nice seamless pipes! -

Ms YuniYou're so kind to provide us so good 304 mirror sheets. We use these plates to make elevators. Thank you!

Ms YuniYou're so kind to provide us so good 304 mirror sheets. We use these plates to make elevators. Thank you!

ASTM JIS Welded Stainless Steel Pipe Seamless 316 Tube 316L Bright Annealing

Product Details

| Standard | ASTM | Type | Seamless Welded |

|---|---|---|---|

| Steel Grade | 316, 316L | Application | Industry Construction |

| Outer Diameter | As Customer Requirement | Processing Service | Bending, Welding, Decoiling, Punching, Cutting, Moulding |

| Grade | 300 Series | Alloy Or Not | Is Alloy |

| Surface Finish | NO.1 NO.2D NO.2B BA NO.3 NO.4 | Invoicing | By Theoretical Weight |

| Delivery Time | 15-21 Days | Material | 316, 316L |

| Color | Sliver | Shape | Round |

| Technique | Cold Drawing Or Casting | Finish | Annealed & Pickled, Bright Annealing, Polished |

| Port | Shanghai Port | ||

| Highlight | ASTM JIS Welded Stainless Steel Pipe,Seamless 316 Stainless Steel Pipe,Bright Annealing Stainless Steel Pipe |

||

Product Description

ASTM JIS 316 Steel Tube 316L Seamless Welded Stainless Steel Pipe

316 / 316L STAINLESS STEEL PIPE

These grades of austenitic stainless steels are similar to 304 and 304L, but with the addition of molybdenum. The addition of molybdenum improves the alloys corrosion resistance, particularly with higher resistance to pitting and crevice corrosion in chloride environments. The austenitic structure allows excellent toughness, even down to cryogenic temperatures. These grades have excellent weld-ability, with or without the addition of filler metal.

These grades of austenitic stainless steels are similar to 304 and 304L, but with the addition of molybdenum. The addition of molybdenum improves the alloys corrosion resistance, particularly with higher resistance to pitting and crevice corrosion in chloride environments. The austenitic structure allows excellent toughness, even down to cryogenic temperatures. These grades have excellent weld-ability, with or without the addition of filler metal.

Corrosion tested to MIL-P-24691/3 or A262 Practice E

| Typical Chemical Composition % (max values, unless noted) | ||||||||

| Weight % | C | Mn | P | S | Si | Cr | Ni | Mo |

| 316 | .08 | 2.00 | .045 | .030 | 1.00 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 |

| 316L | .035 | 2.00 | .045 | .030 | 1.00 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

| Typical Mechanical Properties | |||||

| Grade | Tensile | ||||

| Ultimate/Min | Yield/Min | Elongation/Min | |||

| KSI | MPA | KSI | MPA | % | |

| 316 | 75 | 515 | 30 | 205 | 35 |

| 316L | 70 | 485 | 25 | 170 | 35 |

Recommended Products